- 82H Elizabeth Knox Place , Glenn Innes , Auckland

- team@aei.co.nz

Working Hours:

Monday

9:00AM to 5:00 PM

Tuesday

9:00AM to 5:00 PM

Wednesday

9:00AM to 5:00 PM

Thursday

9:00AM to 5:00 PM

Friday

9:00AM to 5:00 PM

Saturday

Request

Sunday

Request

Get In Touch:

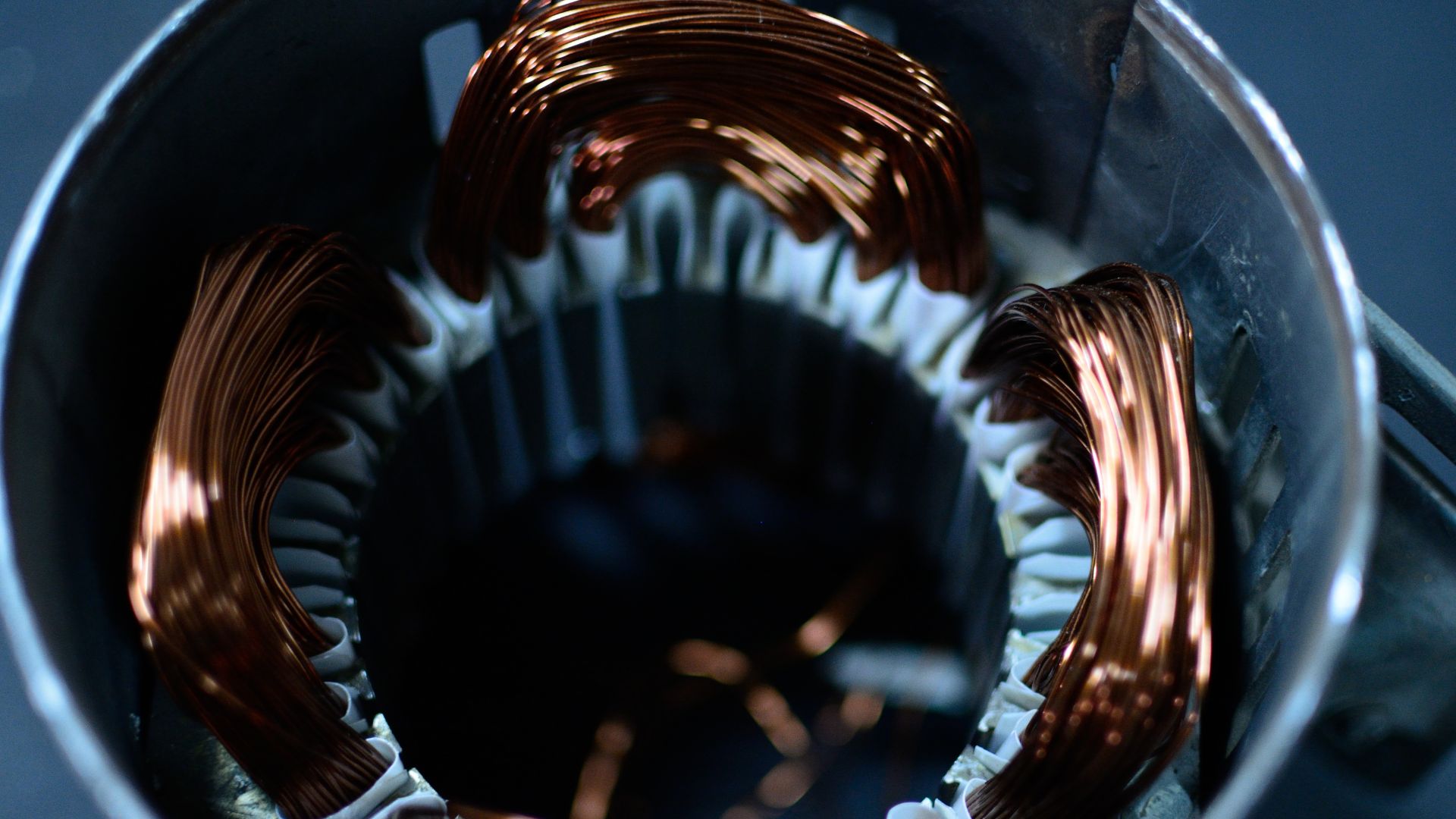

Comprehensive Electric Motor Monitoring Services for Optimal Performance and Efficiency

Ensure the longevity and efficiency of your electric motors with our specialized Electric Motor Monitoring services. At Auckland Electrical Inspections LTD, we use advanced diagnostic tools to monitor the performance of your motors in real-time, detecting potential issues before they lead to costly failures or downtime. Our monitoring services help you maintain optimal efficiency, reduce energy consumption, and extend the lifespan of your electric motors.

"With our Electric Motor Monitoring services, you can prevent costly failures, reduce energy waste, and ensure your motors run at peak performance every day."

Our expert team conducts thorough assessments, analyzing parameters such as temperature, vibration, and electrical load to ensure your motors are operating within safe limits. We provide detailed reports with actionable insights, helping you make informed decisions about maintenance and repairs. Whether in industrial, commercial, or residential settings, our Electric Motor Monitoring services are tailored to meet your specific needs, ensuring continuous and reliable motor performance.

Regular monitoring not only helps prevent unexpected motor failures but also enhances energy efficiency by identifying inefficiencies that may be costing you money. With Auckland Electrical Inspections LTD, you can have peace of mind knowing that your motors are being watched closely, allowing you to focus on your core business without worrying about equipment failures.

What is Electric Motor Monitoring, and why is it important?

Electric Motor Monitoring is the process of tracking the performance and health of electric motors using sensors and diagnostic tools. It's important because it helps detect potential issues early, preventing motor failures, reducing downtime, and improving energy efficiency.

How often should electric motors be monitored?

The frequency of monitoring depends on the usage and criticality of the motor. For high-demand motors, continuous or regular monitoring is recommended, while less frequently used motors may require periodic monitoring during maintenance checks.

What parameters are monitored during Electric Motor Monitoring?

Key parameters monitored include temperature, vibration, electrical load, and motor speed. These factors provide a clear picture of the motor's operating conditions and help identify any deviations from normal performance.

Can Electric Motor Monitoring save money on energy costs?

Yes, Electric Motor Monitoring can help save on energy costs by identifying inefficiencies in motor performance. By optimizing the motor’s operation and addressing issues early, you can reduce unnecessary energy consumption and lower operational costs.